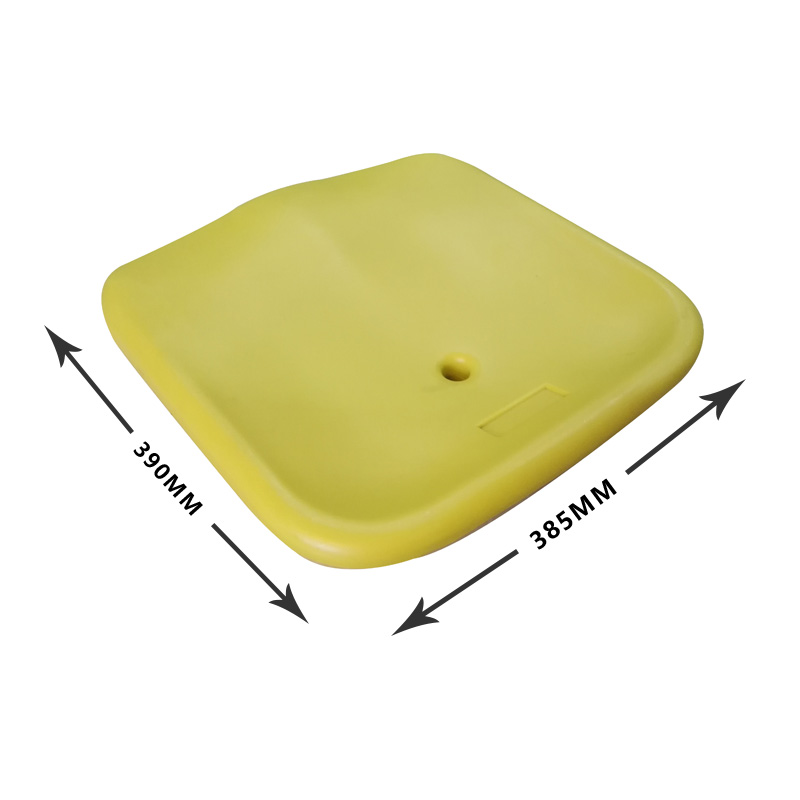

Back and seat: Made of high-density polyethylene as raw material, produced by the most advanced hollow plastic technology, with excellent impact resistance, heat resistance, corrosion resistance, and added a special anti-aging agent to maximize the ground slows down the speed of aging and fading, and greatly improves the service life.

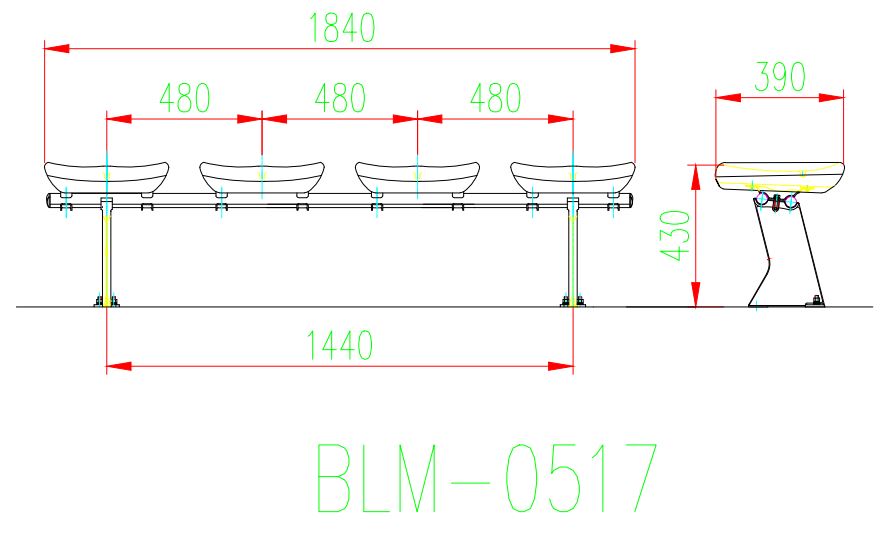

Bracket: Precision casting made of high-quality steel. The exterior of the outdoor seat is made of integral hot-dip galvanizing, and the exterior of the indoor seat is of electrostatic spray. The style is novel and reasonable, durable, and has good anti-corrosion performance. The feet can be fixed with standing feet, side-mounted feet, movable feet and footrests.

Blow molding bucket outdoor chair model — Made in accordance with ergonomic design, the overall effect is beautiful and luxurious after installation. It is very comfortable to seat, people will not feel tire although seat on this chair very long time.

It resistant to most chemicals, UV fading and high or low temperature weather outdoor use. UV protect and to resist from +50℃ to -30℃. Automatically tipping seat (gravity/spring flip up system).

Formula and technology from Japan to produce back and seat, in our factory we use all production lines imported from Japan, all machines are imported from Japan, our engineers are also come back from Japan in this filed. The material of high density polyethylene is imported from Korea. Dainippon Ink (DIC Corporation) color concentrate, anti-ageing, fire retardant, moisture resistivity.

Seats with hyperboloid and the hollow surface layer structure, so the seat is very strong and safe to seat.

There are some hidden screw nuts at two side of chair so that metal parts will not take trouble to people.

We use expansion bolt to install the seat, drilling degree of unity in order not to break the waterproof layer of step.