Product Description

1. The seat back and seat cushion should be cold-foamed polyurethane foam, the seat foam density is 45~50kg/m³, the back foam density is 35~40kg/m³, the shore hardness is 52, and the oxygen index is ≥28; resilience performance Grade A ≥45%; compression permanent deformation grade A ≤5.0%; the external dimensions after foaming require ±5mm testing. The surrounding and waste edges of the cotton should be corrected to prevent the foamed cotton from showing holes, different softness and hardness, lumps, and defects in the shape of the cotton.

2. The back and outer panels are multi-layer hot-pressed solid wood panels (16mm±0.5mm). The outer panel of the seat is a hot-pressed multilayer solid wood panel with a thickness of 15mm±0.5mm, and 36 sound-absorbing holes are added. The seat cushion is equipped with an S-shaped spring. Spring steel wire: serpentine spring steel wire diameter: 3.0~4.0mm; concave (or cloth-covered) spring wire diameter: 2.3~3.0mm. The seat bottom adopts a unique sound-absorbing panel with perfect sound-absorbing function. The upturn of the seat cushion adopts a torsion spring buffer rebound design, accurate reset, low noise, and the noise level is not more than 25 decibels.

3. The seat frame should be made of high-quality aluminum alloy, which is formed by die casting at one time, and is protected by polishing and spraying. The total weight of the armrest is 3.125kg, which fully guarantees the stability and stability of the support. A solid seat shaft of ф14mm is installed at the end of the seat bag, and both ends of the seat shaft are directly connected with the aluminum alloy chair legs to ensure beauty and stability.

4. The handrail panel should be solid beech handrail, coated with polyester polished paint, which is beautiful and durable.

5. The writing board should be made of ABS composite material for one-time molding, the rotating shaft adopts a unique upright 90° overturning positioning device, and the supporting and connecting structure is made of aluminum alloy die-casting.

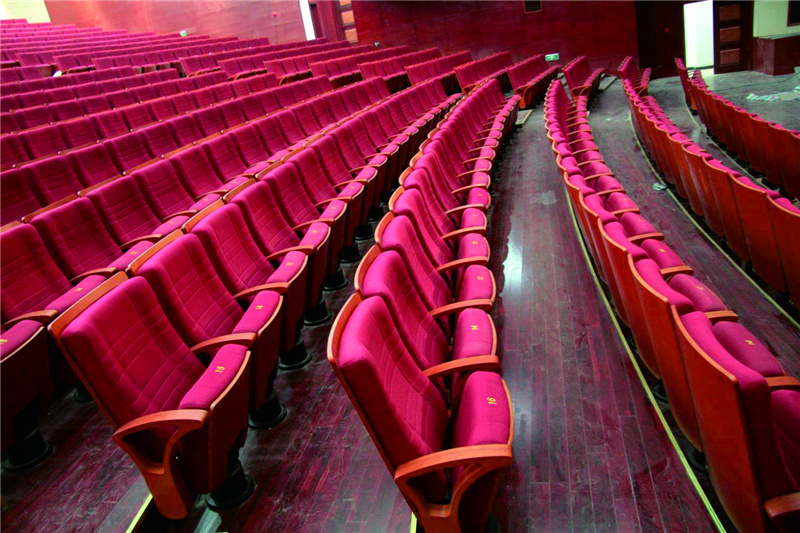

6. There are many varieties of seat fabrics for customers to choose, and flame-retardant treatment, its flame-retardant performance is tested according to the GB/T5455-97 method, all performance indicators can reach GB-5022-95 building interior decoration design Class B1 standard for the burning performance of decorative fabrics in the fire protection code.

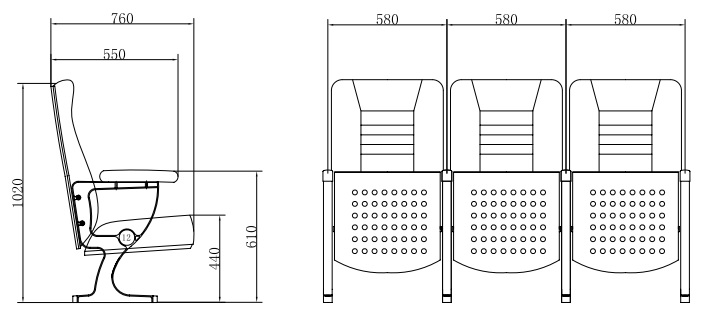

7. Installation error: back height error ±5mm, seat height error ±5mm, armrest height error ±8mm, back slope (front-to-back difference) error ±10mm.

Material Description

Back shell board: ABS injection plastic shell, burst size of carbine reach china national standard.

Seating shell board: ABS injection plastic shell, burst size of carbine reach china national standard, paired with an internal layer of sound-absorbing foam, acoustical seat pans enrich the sound and augment the andience’s listening pleasure.

Foam of cushion: High rebound stereotypes of cold foam sponge, the density of foam reach 60-110kg/m³.

Fabrics: Hemp soft cloth, flame retardancy, abrasion resistant, resistance to soiling, antistatic, anti-fade, anti-friction, and comfortable.

Rebound structure: Damping design, reset exactly, low noise, noise level: ≤ 20 decibel.

Arm frame: Moulded aluminium armrest & leg.

Arm cover: ABS retractable writing board.

Writing board: ABS retractable board, A3 size around.