Performance Comparison of ABS Engineering Plastics and High-density Polyethylene

1. Brief introduction of raw materials:

(1) ABS engineering plastic refers to acrylonitrile-butadiene-styrene copolymer, which is a kind of thermoplastic polymer material.

(2) High-density polyethylene is a non-polar thermoplastic resin with high crystallinity.

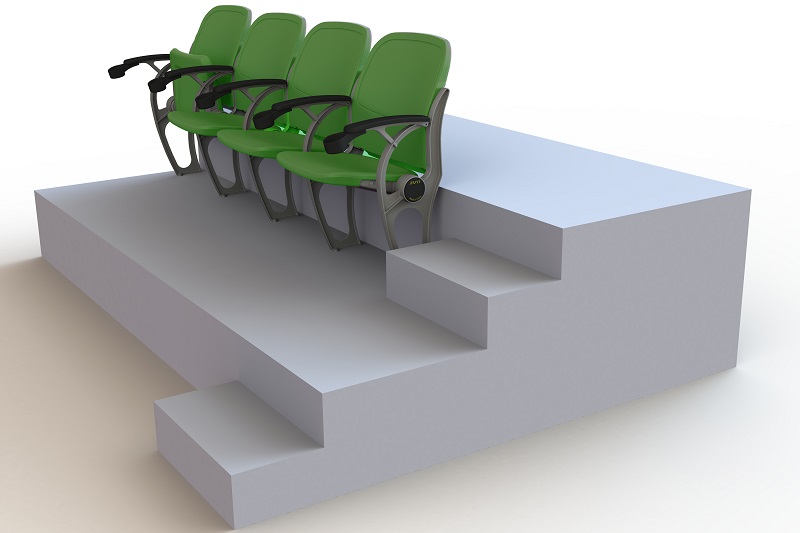

2. Comparison of the seat production process of the two raw materials:

(1) Due to the different materials of the two materials, when high-density polyethylene is used to make seat products, the production process is hollow blow molding, and the production process of ABS engineering plastic is injection molding.

(2) Analysis of the advantages and disadvantages of the hollow blow molding process: First of all, high-density polyethylene is lighter than ABS engineering plastic in terms of product weight, and is easy to install and transport. The injection parison is formed by the die under lower pressure, so the residual stress of the product is small, and the performance of various strains such as tensile, impact, bending and environment is high, and it has better performance. Finally, the hollow blow molding seat feels more flexible than injection molded seats, making it more comfortable to sit for a long time and is more ergonomic.

(3) Analysis of the advantages and disadvantages of injection molded products: All the parisons made by injection can be blown into the blow mold for inflation molding, which reduces the waste of molding materials and saves the finishing time of the product. However, the temperature of the injection parison is relatively high. After the high-temperature parison is inflated in the injection mold, a longer cooling and setting time is required, which prolongs the entire molding cycle of the product and reduces the production efficiency; the internal stress of the injection parison is relatively large, and the mold is changed. It is prone to uneven cooling at times, which increases the risk of stress cracking in polyolefin plastic blow-molded containers.

Summary:

High-density polyethylene has stronger ductility and tensile strength than ABS engineering plastics, and is more suitable for seat modeling and other processes.

HDPE has stronger UV resistance and puncture resistance than ASB engineering plastics.

High-density polyethylene has stronger environmental performance than ABS engineering plastics, and is widely used in food packaging, fiber packaging, daily chemical packaging and other fields.

In summary, it is recommended to choose the high-density polyethylene as the seats’ materials.

JUYI Seating Company’s stadium seats, all choose the one-time use the HDPE as the material, we never used any recycled materials added to the raw materials.