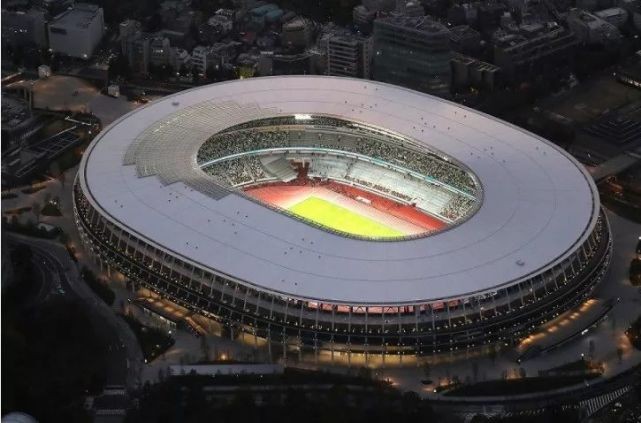

The opening of the Tokyo Olympics! The new Tokyo National Stadium, main venue for the Olympics!

From 19:00 to 22:30 on July 23th, the 32nd Olympic Games, which will be postponed from 2020 to this summer, will kick off in Tokyo. Although affected by the epidemic, the Tokyo Olympics was postponed by one year, but this sporting event still attracted the attention of the world.

For this Olympic Games, Japan can be said to have “spent its blood”, just renewing the stadiums used for the game has spent 252 billion yen. The highlight is the Tokyo New National Stadium, which cost 100 billion yen.

The Tokyo New National Gymnasium was converted from an old gymnasium originally built in 1958. It was once the main stadium of the Tokyo Olympics in 1964. The refurbished stadium can accommodate 68,000 spectators. It is also a stadium that hosts many sports events such as the opening and closing ceremonies of the Olympic Games and football matches. Unfortunately, due to the epidemic, Japan has banned foreign tourists from entering the country. Only a few local Japanese people will be able to watch the games and experience the Olympic venues designed by the famous Japanese architect Kengo Kuma.

The New National Arena is located in Shinjuku, Tokyo. This is a famous and prosperous business district in Japan. It is different from the commercial CBD with only skyscrapers. There are also quite large parks-Meiji Jingu Gaien and Shinjuku Gyoen, New National Arena It was built in the forest of the outer garden of Meiji Jingu.

The design concept of the arena – maintain harmony with the surrounding park environment

The new National Stadium, with a maximum height of only 49 meters, coupled with the design that fits the atmosphere of the forest, enables the original environment of the surrounding park to be fully respected and protected. Green concept, low-carbon design. The design concept of the main stadium is “wood and green”. The 108 load-bearing columns are all made of steel and wood mixed structure, and the wooden building materials from all over Japan are widely used inside, which echoes the four-layered wooden eaves on the outside.

The mixed structure of wood and steel supports a large roof with a total weight of 20,000 tons. A lot of wood is used to highlight Japanese traditions. The outer wall of the building uses fir, and the supporting structure of the roof uses larch. The sports venue full of “greenery” uses traditional architectural techniques and design elements to create a 360-degree surrounding eaves roof.

The wood raw materials are all cedar and pine wood provided by 47 prefectures and prefectures across Japan, which greatly reduces the carbon emissions during transportation. It also symbolizes the unity and mutual assistance of the whole people to participate in the construction of the main Olympic stadium. The height of the venue was deliberately lowered to reduce the sense of oppression caused by the building. Green plants have been planted on each floor of the venue to highlight the importance of the ecological environment. It is also hoped that the venue can be integrated into the surrounding greenery.

In order to solve the government’s more important construction cost problem, a gentler roof and sunken runway were adopted. The stadium structure includes 5 floors above ground and 2 floors underground, and the track and field stadium is equivalent to the location of 2 floors underground. Through the sunken design of the eaves, the height of the stadium was finally successfully controlled within 50 meters. The total area has been reduced, and the budget has been reduced by 40% accordingly. Although there are about 60,000 spectators in the stadium, it is not too oppressive. The warmth of wood not only eases the rigid texture inherent in large buildings, but also contrasts with the adjacent lush Meiji Jingu Gaien.

Many sports venues mostly only consider the perspective of the spectator, while the “New National Arena” incorporates the perspective of the athletes. For example, the seats in the stadium use five earth colors, including dark brown, dark green, gray, yellow-green, and white. These colors are like fallen leaves, arranged and staggered like mosaics. Let the athletes feel as if they are in the forest in the stadium, can feel at ease, relax, and give full play to their strength.

The lawn on the site is a natural lawn. In order to have the most suitable growth environment throughout the year, an underground temperature control system is also installed. For the track and field track, the well-known product “high-speed track” made of high-elastic synthetic rubber made by the Italian company Mondo is used. It is hoped that athletes can use this to set off an upsurge of creating good results.

Stadium seats make our stadiums different, the stadiums can function better, and the stadiums are more convenient to use. The stadium seats produced by JUYI Seating Company, from raw material processing to final seat molding, are not polluted during the production process, and the seats fully comply with the current green environmental protection requirements. Modular design makes installation and maintenance easier and faster. Gymnasium seats are widely used in various indoor and outdoor venues or auditoriums and other public places that often need to hold various different activities. Gymnasium seats have a variety of styles and colors. The color of the gymnasium seats can also be selected according to user needs. As there are many different options for stadium seats, it can easily meet the needs of various occasions.

JUYI Seating Company is a comprehensive seat manufacturer and supplier integrating design, development, production, sales, installation and maintenance. The company mainly produces telescopic event stands, stadium seats, auditorium chairs, theater seats Chairs and so on. In recent years, the company has successively undertaken large-scale domestic and overseas projects such as the 2008 Beijing Olympic Games and the 2014 Sochi Winter Olympics in Russia. The products have been exported to 65 countries around the world.

The quality of JUYI Seating Company’s products stems from the quality control of the complete path, from the fine selection of raw materials from the very beginning to the strict input inspection throughout the entire manufacturing process, packaging, transportation, delivery, supervision and after-sales service. This process is characterized by a series of strict control procedures and quality standards accompanying different stages.

JUYI Seating Company focuses on products and processes, and adopts the most modern and automated production technology to ensure the continuity of excellent results. The company’s focus is also on the experience, ability and professionalism of the employees, because their job purpose is to ensure that the final product meets the customer’s requirements and special needs.